Natural wood tones – pale, but resistant to dirt, scratch-proof, and easy to clean – are among the key demands that consumers are placing on kitchen cabinet manufacturers.

Transparent Finish

The U.S. is currently the largest kitchen cabinet market in the world. According to research from Freedonia, the demand for kitchen cabinets in the U.S. is growing at an average annual rate of 2.9%, projected to reach a value of $20.9 billion by 2026. As a global consumption leader, U.S. market trends heavily influence international preferences.

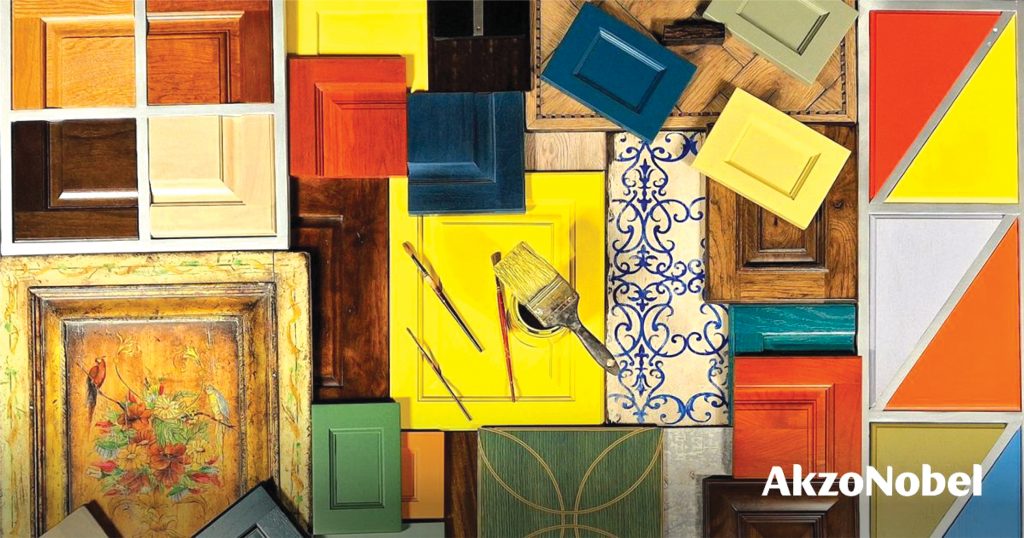

Prakash Kumar, Regional Marketing Manager, Wood Finishes & Adhesive, APAC, AkzoNobel, said that American consumers typically favor traditional finishes. They favor transparent coatings that reveal the natural wood grain, commonly referred to as a “transparent finish.” However, younger consumers are increasingly embracing more modern furniture styles, including kitchen cabinets, which are gradually shifting towards brighter pigmented finishes, more contemporary colors.

Agreeing with these sentiments, Dang Vu Tuong, Country Technical Service Manager, Wood Finishes Asia, AkzoNobel, stated that consumers are demanding natural tones, but the common trend is for paler shades. The natural variations in wood colors pose challenges for surface finishing. “Our technical team has to study how to maintain a natural pale tone on the wood while ensuring color consistency across the entire product surface,” Tuong explained.

For colored kitchen cabinets, Tuong noted that basic, traditional colors like white and grey are declining in popularity, being replaced by black or green. These colors necessitate the development of new paints with higher color concentrations. Compared to other product categories, kitchen cabinets change more slowly, often taking years to establish a new color trend. Tuong predicted that metallic colors like gold, silver, and bronze could become popular in the coming years.

High Technical Requirements

Beyond color and high-quality surfaces, kitchen cabinet manufacturers must meet standards for scratch resistance, fingerprint resistance, and ease of cleaning. Chris Lee, Regional Sales Manager, Wood Finishes Asia, AkzoNobel, shared, “AkzoNobel has invested significantly in developing perfect surfaces for kitchen cabinets, with anti-scratch systems, low dirt retention, fingerprint resistance, and easy cleaning.”.

Kitchen cabinets is a unique segment, compared to other furniture types, requiring higher surface finishing standards, due to their exposure to environmental factors like grease and cleaning agents. The kitchen environment, with its fluctuating temperature and humidity especially during cooking demands adaptable surface coatings. Furthermore, products exported to the U.S. must be self-assembled by consumers, emphasizing the need for consistent color across all production lines. AkzoNobel’s technical team regularly visits kitchen cabinet factories to assist manufacturers in meeting these requirements, ensuring smooth production, uniform color, and high quality.

AkzoNobel is not just a product supplier; rather a strategic partner to kitchen cabinet manufacturers by offering support throughout design, production, and after-sales processes. Over the years, AkzoNobel’s new product development team have developed many unique finishes, serving interior manufacturing businesses in Vietnam. With the advantage of having a color research center based in the U.S., AkzoNobel keeps up with consumer trends in the U.S. market. “AkzoNobel’s U.S. lab is also well-versed in meeting chemical regulations for this market, ensuring that banned substances are excluded from furniture products, helping manufacturers avoid risks when exporting to the U.S.,” said Chris Lee.

According to Chris Lee, the materials used in paints depend on customer requirements. Following AkzoNobel’s sustainable development goal, the product development team selects materials that not only meet customer demands but also ensure environmental friendliness. All AkzoNobel’s paint products comply with strict import standards in the U.S. “With UV paints, AkzoNobel ensures that the painting process is easy to apply, quick to dry, energy-efficient, time-saving, and minimizes emissions. In the near future, we plan to expand our water-based systems to wood coatings, further enhancing green standards for indoor and outdoor products”, Chris Lee emphasized.

By Phuong Mai